reflow simulator

We scientifically analyze heat and create heat.

Small Reflow Simulator

(With Ceramic Heater and Halogen Heater)

Overview

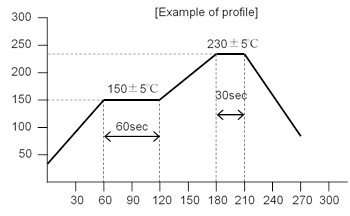

Attached to an X-ray device, this heating unit is used to simulate the reflow status of solder to observe and determine the degree of melting and temperature conditions of the sample solder using the integrated application of X-ray image and temperature profile

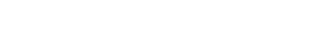

■ Heating Room (heater)

■ Unit Overview

Features

● Thin, small heating unit makes it easy to determine the scaling factor of X-ray image, and the glass window on the top allows for check of the sample setup.

● Stable profile can be achieved by the halogen and ceramic heaters over and under the sample respectively.

● Our large soaking ceramic heater can heat the sample directly from the bottom without being affected by the X-irradiation to achieve rapid heating of a large portion of the sample.

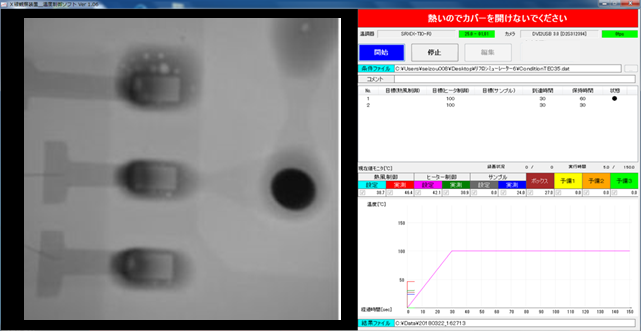

● With the integrated application of X-ray image and heat control, the X-ray image and temperature profile of the sample can be recorded in real time (max. 10 frames per second) during heating. Up to 10 heating programs can be registered.

● As an optional specification, an atmospheric gas such as N2 can be introduced into the heating room of the unit, enabling the simulation of the sample in a special atmospheric environment.

■ Operation Screen of Integrated Heat Control/Image Application

Specifications

| Power source | AC200V 60Hz 20A *2 |

|---|---|

| Heater capacity | Halogen + Ceramic, total 2700W |

| Furnace heating capacity | MAX 350℃ |

| Maximum substrate size | 90mm(W) × 90mm(D) |

| Heating method | Near infrared (halogen) + ceramic heaters |

| Temperature control point | Two points (atmosphere and ceramic heater) |

| Control method | Programmatic PID control |

| Accessories | PC of integrated application, control panel |

| Approved standard | CE |

*1 Maximum 150mm×150mm available at the option.

*2 The power source and the heater capacity depend on the supported substrate size.